Multi Tasks Team

Our designers determine that each design should go through the process of:

- Form finding & Finite element analysis.

- Connection detail design & Climatically analysis.

Creative Freedom

Our team of designers offers the following services:

- Sketch drawings & 3D models

- Photo montages & Design consultancy

Detail Driven

In the design process, the following criteria is considered:

- Fabric options

- Fixing and fittings

Designed to Comply

We generate computer models with load analysis calculations and tensile structure engineering criteria. These calculations show us loads on the fabric, which determines stress on the structure. With this information, we factor in:

- Size of foundations

- Size of steelwork

- Pre-stress of fabric

Engineered to Perform

As designers, we like to push the boundaries of what fabric can do – we do that by being masterful at tensile structure engineering. When engineering tensile fabric structures, we take into consideration:

- Environmental loads

- Load transfer

- Deflections

Testing

No two projects are the same. Some are more challenging than others. In our line of work, there is no time to figure things out on site. It all must be considered and tested in our factory so that when we show up, we are ready to get started with confidence. In our factory we: Create mock ups Conduct fabric tests

On Site Manufacturing

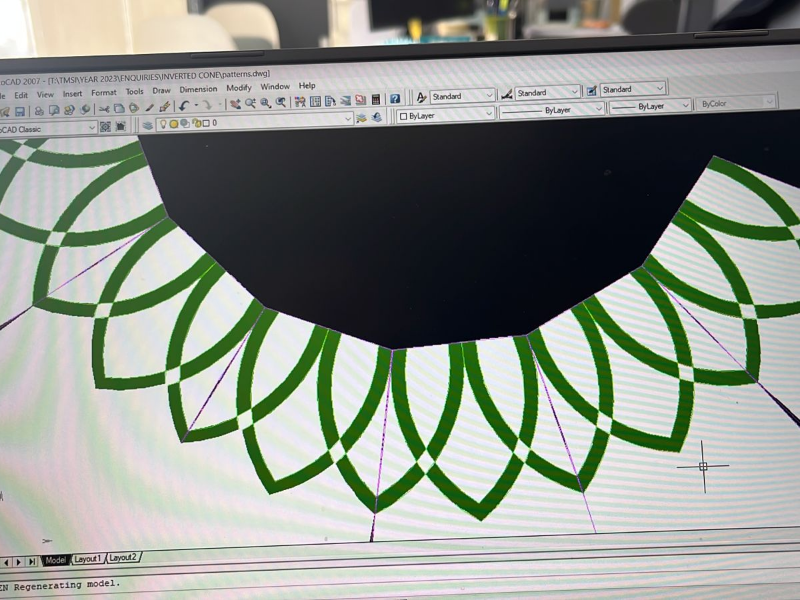

As tensile fabric manufacturers, we have a factory which offers clear span working space for the assembly of large scale fabric projects. Patterns, determined by our designers, are sent to our factory to be efficiently cut with minimal wastage. After fabric patterns are cut they are placed side by side according to a master plan and then assembled. The process includes:

- Patterning

- Testing

- Cutting

- Joining

- Detailing

Site Management

Our team of supervisors are happy to take on a site management role. Their job is to work closely with our office to coordinate our site staff and local labor. Our knowledge and expertise in installation allows us to:

- Quickly resolve issues on site

- Supervise cranes and mechanical equipment

- See the project through to handover

Safety First

Installing tensile fabric structures can involve potentially complicated site operations. A safe site is one where all employees are confident and qualified to carry out tasks they are assigned. From the onset of a project, we establish the following:

- Health and safety plans

- Method statements

- Risk Assessments

Design

We have a professional team of engineers, who can cover all the technical obstacles and provides all project needs from designing, drawing, and patterning

Engineering

Preparing the project’s requirements, and all the needed material from our local and international suppliers to ensure that everything is ready to proceed

Manufacturing

Our team collects all the technical data and starts with manufacturing the project parts using the latest technologies to obtain the best quality

Installation

Installation teams work on a daily basis in an organized structure to cover all the areas. They will be on time with the needed equipment for all kinds of projects

Architectural Lighting

Creative Freedom

From basic architectural lighting systems to responsive and interactive lighting, Our team designs to the specifications of each project. The extraordinary and varied effects of a thoughtful lighting system are MSTECH’s expertise. Perfect for:

- Defining a space

- interest or creating a focal point

- Way finding

Applications

MSTECH is equipped to take on the most creative lighting projects. Today’s materials from PVC Polyester to PTFE Glass to ETFE Foil all lend themselves to architectural lighting. Applications include:

- Branding through the use of color

- Way finding – directing people

- Enhancing and changing a space

Expanded MESH

TMSI offers more than 25 designs of expanded MECH realized in different materials and with varying thicknesses to the market.

The goal of the TMSI team is to give life to the architectural project through the study of the best engineering and structural solutions, to be able to perfectly combine aesthetics, design, practicality, and innovation.

HIGHLY EFFICIENT

Due to the continuous connection throughout each sheet of expanded metal mesh, electricity, magnetic flux, and heat can all pass through.

AESTHETICS

Expanded mesh is available in a wide array of colors, materials, and designs, and it can be used to stunning effect.

COMPOSITE SUBSTRATES

Expanded mesh can be easily combined with other materials such as glass or plastics for added strength and flexibility.

Maintenance

Our team of supervisors will work closely with our office to coordinate some building warranties and health and safety regulations require that tensile structures are subject to regular inspection and maintenance to ensure their longevity and reliability. While our structures are built to last, weather conditions, accidents and misuse do mean they can deteriorate over time. This is why we offer the following:

Repairs: onsite for small jobs or larger sections can be manufactured in our factory

A 24-hour response service is available by offering emergency support and technical expertise